- 50 Ohm Pcb Trace Width Calculator Estimate

- 50 Ohm Pcb Trace Width

- Trace Width Current Calculator

- Pcb Trace Size Calculator

PCB Trace Width Calculator & PCB Trace Resistance Calculator per IPC-2152. Calculates the current a conductor needs to raise its temperature over ambient per IPC-2152. Now also calculates DC resistance with temperature compensation. Other conductor properties include: Conductor skin depth Conductor voltage drop Conductor DC resistance. The original equations are in Transmission Line Design Handbook by Brian C Wadell, Artech House 1991 page 79. The equations use 'a' for the track width and 'b' for the sum of the track width plus the gaps either side. With the Multi-CB impedance calculator, you can calculate the approximate impedance dimensioning of your PCB / high frequency circuit board. These are pure estimates to obtain a guideline. The surface finish is neglected. For exact impedance calculation, we recommend the software from Polar Instruments. Component: Copper Traces Purpose: Interconnect two or more points Problem: Inductance and Capacitance x = length of trace (cm) w = width of trace (cm) h = height of trace (cm) t = thickness of trace (cm) e r = PCB Permeability 0.8mm (0.031”) trace on 0.8mm (0.031”) thick PCB (FR-4) has: ˜ 4nH and 0.8pF per cm ˜ 10nH and 2.0pF per inch.

Table of Bittele production minimum sizes

| Copper Weight | 0.5oz | 1oz | 2oz | 3oz | 4oz or above | |

| Outer layers | Minimum Trace Width | 3mil | 4mil | 5mil | 6mil | RFQ |

| Minimum Trace Spacing | 4mil | 5mil | 7mil | 10mil | RFQ | |

| Via holes to other copper feature | 7mil | 9mil | 12mil | 16mil | RFQ | |

| Inner layers | Minimum Trace Width | 3mil | 3.5mil | 5mil | 6mil | RFQ |

| Minimum Trace Spacing | 3mil | 4mil | 6mil | 9mil | RFQ | |

| Via holes to other copper feature | 7mil | 8mil | 11mil | 15mil | RFQ |

Notes:

The formula for calculating allowable current through a trace is published in the IPC-2221 standard section 6.2 as shown below.

Internal traces : I = 0.024 x dT0.44 x A0.725

External traces: I = 0.048 x dT0.44 x A0.725

The trace width can then be calculated by re-arranging this formula to determine the cross-sectional area that our desired current can safely pass through.

Area[mils^2] = (Current[Amps]/(k*(Temp_Rise[deg. C])^ 0.44))^(1/0.725)

Then, the Width is calculated from the cross sectional area for a chosen thickness:

Width[mils] = Area[mils^2]/(Thickness[oz]*1.378[mils/oz])

As per IPC-2221 for internal layers k = 0.024 and for external layers: k = 0.048

Disclaimer:

These calculations are industry standard and believed to be correct, but not guaranteed. May not be appropriate for all designs.

Trace Width Calculator FAQs

Q: Is there a limit to the amount of current this tool can calculate a width for?

A: Yes. The IPC-2221 data from which these formulas are derived only covers up to 35 Amps, trace width up to 400 mils, allowable temperature rise from 10 to 100 degrees Celsius, and copper of 0.5 to 3 ounces per square foot. If used outside of these ranges, this calculator will extrapolate thus becoming more inaccurate with higher currents.

Q: Instinctively, I would predict that internal trace widths would need to be less than external traces since the external trace can peal off of the board if too hot. Your calculator gives the opposite result. Why?

A: External layers have better heat transfer than internal layers as air dissipates heat due to convection, while the internal dielectric does not conduct heat as well. Since the goal of the Trace Width Calculator is to prevent an excess temperature rise of the traces, it makes the internal traces wider because they store more heat. In the case of a circuit in vacuum, or in a potted assembly, external layers do not have the benefit of heat convection in the air thus you should use the internal trace width for all traces.

Q: What does temperature rise mean in this context?

A: Temperature rise is the difference between the maximum safe operating temperature of your PCB material and the typical operating temperature of your board. Higher current flow increases the temperature of the copper traces therefore, temperature rise is a design parameter for how much added heat you would like to design for. Based on this limit the formula chooses a width to stay within it. Ten degrees is a safe rule of thumb for most applications. If you need to reduce trace width then you can increase this value if your PCB material and operating temperature allows.

Q: In some cases thermal relief lines called 'wagon wheels' or 'spokes' are used when connecting a pad to a large copper area for easier soldering. I used the trace width calculator and the width given for these spokes are so wide that it is impractical to use. How should I calculate these?

A: Thermal relief spokes are usually very short. The formula this calculator is based on was determined empirically for reasonably long transmission lines. The purpose of this calculator is to prevent traces form overheating, thus if these spokes are connected to dissipate heat then they do not need to be as wide as this tool predicts. Please consult other PCB design resources for this issue.

Q: What unit of measure is Mils?

A: A Mil is one thousandth (1/1000) of an inch. Its name is derived from Latin mille meaning thousand. In electronics mil is commonly used but in other disciplines it may be referred to as thou and a mil being a millimeter.

The below is the formula for resistance of a trace:

50 Ohm Pcb Trace Width Calculator Estimate

Resistance = Resistivity*Length/Area*(1 + (Temp_Co*(Temp - 25))Where, Area = Thickness*Width

A copper Thickness of 1 oz/ft^2 = 0.0035 cm

Copper Resistivity = 1.7E-6 ohm-cm

Voltage Drop is Current * Resistance

Power Loss is Current^2 * Resistance

The old expression is, “give them an inch and they will take a mile.” I may not have completely understood that expression when I was younger, but it sure has come into focus now that my teenagers have started asking me for money. On the bright side, there is a lot more room in my wallet these days for things other than cash.

50 Ohm Pcb Trace Width

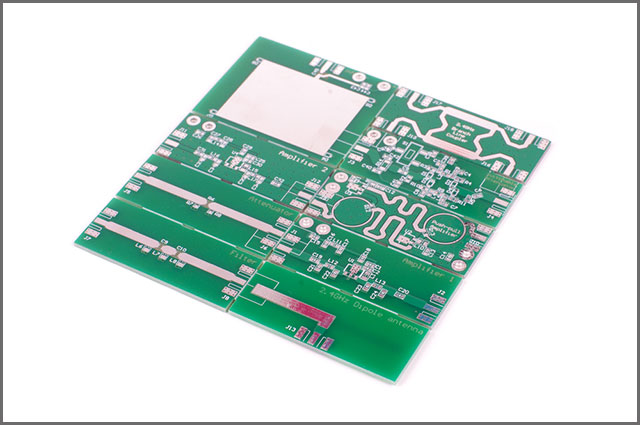

It is not unusual for people to always want more, especially when laying out a printed circuit board. We want more room for placing components, we want smaller traces to make our routing easier, and we want fewer design restrictions so we can easily hook up the connections. Going down this particular path of least resistance, however, usually results in some big problems with our PCB layout. There are reasons why these restrictions are in place, both from a board performance perspective as well as manufacturing. Let’s take a look at some of the common reasons behind PCB trace width and spacing restrictions, and how by working within these restrictions, you can design a better board.

Congested PCB Layout

Performance Considerations for PCB Trace Width and Spacing Restrictions

When trace routing is used to distribute power and ground throughout the components on your circuit board, the traces must be large enough for the current they are carrying. To do this, the trace can be wider, thicker, or both. Whereas trace width is determined by your CAD tool’s routing rules, the thickness of the trace is determined by the amount of copper weight that is used to build that layer of the circuit board. A half ounce of copper spread evenly over a square foot of circuit board will be 0.7 mils thick, one ounce will be 1.4 mils, and so on. To route the correct width trace for power traces then, you need to calculate the current along with the copper weight of the layer. Which layer of the board you are routing on is also important because external layers have better heat transfer than internal layers as the air dissipates the heat better than the internal dielectric layers.

There are also restrictions on traces used for high speed signals such as controlled impedance lines. Using an impedance calculator, you can enter the board width, type of materials, and layer stackup, in order to determine the trace width needed to hold a specific impedance value, such as a 50 ohm line. Amitech living 6xx driver download for windows. High speed design routing will also require certain spacing restrictions as well in order to control noise that could be picked up from adjacent lines that are too close. Serpentine routing patterns for traces that have to be tuned to precise lengths also require specific spacing, which is usually at a ratio of three times the trace width.

Trace Width and Spacing Rules for Manufacturing

So far, we have looked at how trace width and spacing restrictions affect the performance of the board electrically, but there are also manufacturing concerns as well. Traces that are too close to each other or to other metal features of the board could potentially develop shorts during fabrication. Each fabricator will have its own minimum trace width that they will build, but 3 mils is a common minimum spacing value. Copper weight also must be factored in here as well. The higher the weight, the larger the minimum spacing is needed by the fabricator to build the board. Although a higher copper weight is more desirable for routing that carries high levels of current, it can pose a problem for fabricating narrow signal trace widths. Another routing concern is acid traps, which can occur when trace angles are too sharp.

Here are some other manufacturing considerations for trace width and spacing restrictions:

- Traces running between the pads under small surface mount components may have the minimum trace to metal spacing, but can still cause manufacturing problems. The part may not sit squarely resulting in tombstoning, or form a solder bridge with a trace and cause damage if the part is lifted for re-work.

- Metal that is too close to the edge of the board could present depanelization problems. Additionally, exposed copper could come into contact with other conductive elements and cause a short on the board.

- Traces that are too wide on the surface mount pads could form solder bridges with adjacent pads or traces. These could cause excess current or shorts.

- It is also important that drill hole sizes match the traces to which they connect. Although vias run through the board they serve the same function as traces that run along the surface. In many cases, they are extensions of them.

Go to the Experts: Ask Your CM About Trace Width and Spacing Restrictions

The good news is that you have an excellent resource in your contract manufacturer to help you through these types of trace width and spacing restrictions. Your CM has many years of experience building boards of all kinds of different technologies, and they already have the answers you will need for your specific project. The best thing that you can do is to engage early on in your design with your CM to determine the proper trace widths and spacing that your PCB design will need.

Tempo‘s Custom PCB Manufacturing Service

|

Dp-201 dfu drivers download for windows 10, 8.1, 7, vista, xp. At Tempo Automation, we are ready to work together with you from day 1 of the PCB manufacturing process. We have the experience and the resources that you need to answer your design specific questions in order to make sure that your design is manufactured to the highest levels of quality.

Trace Width Current Calculator

Alienware aurora-r3 driver download for windows 10. And to help you get started on the best path, we furnish information for your DFM checks and enable you to easily view and download DRC files. If you’re an Altium Designer or Cadence Allegro user, you can simply add these files to your PCB design software. For Mentor Pads or other design packages, we furnish DRC information in other CAD formats and Excel.

Pcb Trace Size Calculator

If you are ready to have your design manufactured, try our quote tool to upload your CAD and BOM files. If you want more information on PCB trace width and spacing restrictions, contact us.